Asset identification and traceability

"Asset identification and traceability" refers to the ability to determine, label, and trace production assets during the manufacturing process. This includes uniquely identifying raw materials, components, production equipment, and finished products, and establishing corresponding traceability links.

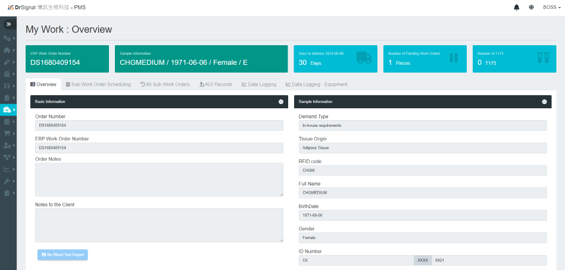

DrSignal's "Cell Preparation Full-Process Traceability Platform" applies IoT (Internet of Things), two-dimensional barcodes, RFID (Radio-Frequency Identification), and other technologies to achieve real-time monitoring and recording of the entire process from order placement, transportation, preparation, inspection, to shipment delivery during the cell preparation process. Such identification and traceability capabilities help improve the visibility and transparency of the production process while ensuring compliance and quality of products.

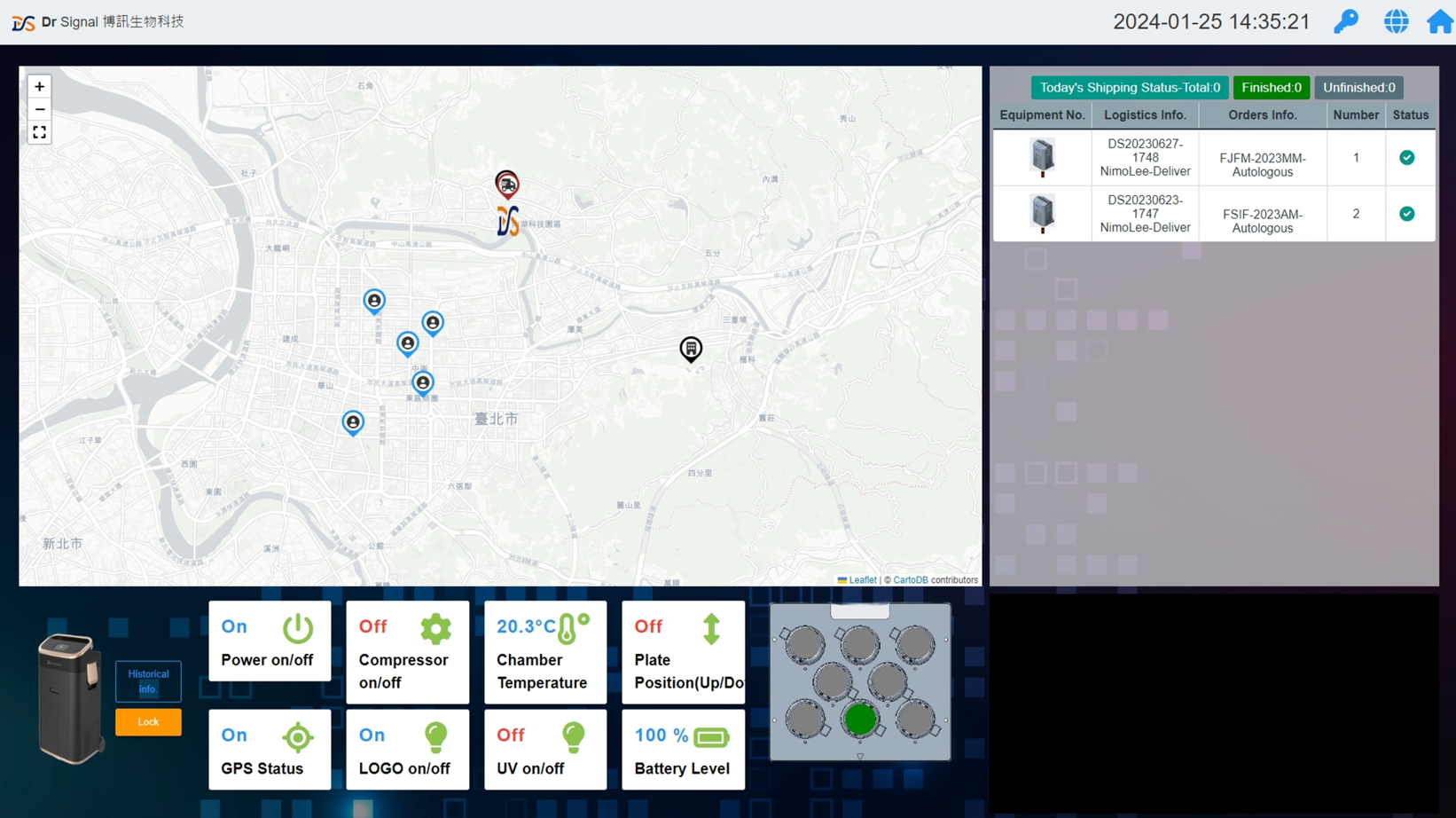

Visual monitoring

"Visual monitoring" refers to presenting key information such as the operational status, data, and quality indicators of various assets in the production environment through charts, graphs, gauges, and alerts. This enables management personnel to instantly understand the production situation, quickly identify issues and anomalies, and take corresponding measures for adjustment and optimization in a timely manner.

Dr.Signal Biotechnology's "Real time Situation Monitoring Center" applies technologies such as data collection, analysis, and visualization to extract data from every production link in the factory. It monitors and analyzes the operational status, production data, equipment efficiency, warehouse inventory, and quality indicators within the factory. This critical data is displayed through an intuitive visualization interface, showcasing key indicators and alerts. Coupled with data analysis and predictive modeling, it provides real-time decision support and optimization suggestions, assisting management personnel in making accurate production instructions and adjustment strategies

AI simulation

"AI simulation" refers to the use of machine learning and data analysis techniques to build models that simulate production environments, production resources, order demands, and other relevant factors. By training and optimizing these models, precise, flexible, and efficient production plans can be achieved, enhancing resource utilization, production efficiency, and customer satisfaction.

DrSignal's "Intelligent Cell Preparation Simulation System" combines simulation technology with AI technologies such as data analysis, machine learning, and deep learning to assist factories in data-driven decision-making and optimization in various cell preparation scenarios.

Resource optimization

Considering factors such as resource capacity, process requirements, and operating time, optimize the allocation and utilization of production resources to ensure the balance and efficiency of production lines, generating optimal production scheduling plans.

Virtual testing

Simulate the execution of scheduling plans in a virtual environment, evaluate the effects of different scheduling schemes, and predict production states and potential bottlenecks, helping to identify and resolve potential production issues in advance.

Real-time optimization

Synchronize with the actual production environment using virtual-physical integration technology, monitor production environments and resource utilization in real-time, and adjust production scheduling according to actual conditions to improve production efficiency and flexibility.

Smart decision-making

"Smart decision-making" refers to the use of data analysis and artificial intelligence technology to provide accurate, real-time decision support from real-time and historical data. By collecting and analyzing big data, the system can predict outcomes, identify risks, and provide optimization suggestions. This helps managers reduce human errors, improve decision-making speed and accuracy, and enables factories to respond quickly to changes, achieving continuous improvement and sustainable development.

Cell growth trends

In the process of cell preparation, the system regularly conducts AOI cell counting inspections for cells and combines the data in the cell database. Using data analysis and machine learning technology, the system predicts cell growth trends and behaviors based on past growth data and cell characteristics. This helps factories predict cell culture outcomes, estimate production time and resource requirements, optimize production scheduling, and ensure more efficient resource allocation.

Predictive maintenance

By collecting and analyzing sensor data, equipment failures can be predicted in advance, and maintenance can be planned proactively to avoid disruptions to production caused by equipment failures. Additionally, the data from predictive maintenance can be incorporated into the AI simulation scheduling model to adapt to the needs and timing of maintenance work, minimizing production interruptions.

Defect detection

During the cell preparation process, cells should be inspected regularly under a microscope to ensure their sterility, cell density, and growth condition. In the past, manual inspection limited the operation time for each microscope to one person, considering human fatigue, with one person being able to operate continuously for a maximum of 1-2 hours per day. Through automation technology combined with image analysis and machine learning, the system can automatically learn and identify features of normal and abnormal cells. This ensures consistent quality in cell culture, reduces the production of defective cells, and makes the detection process more efficient and reliable.