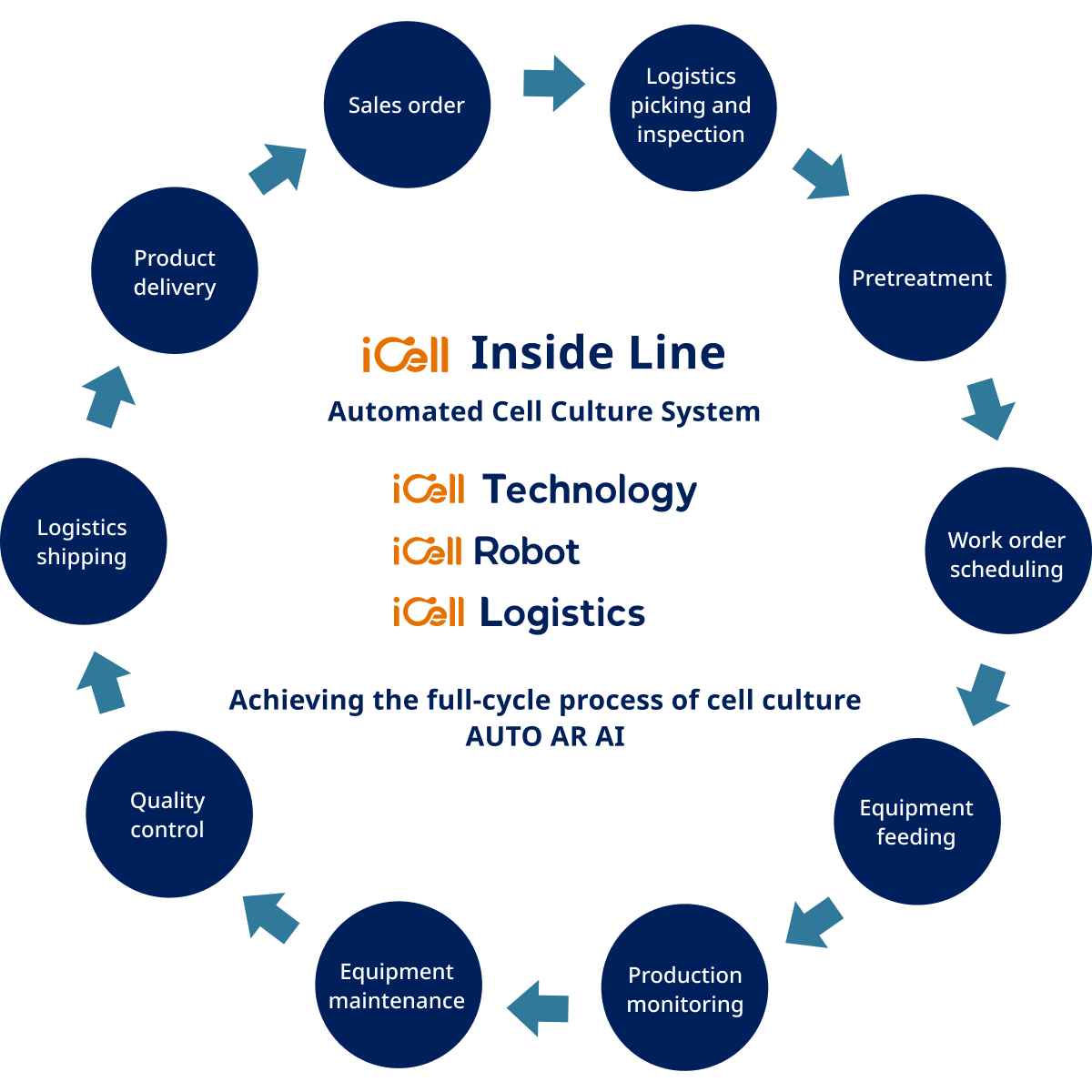

DrSignal started the development project of the "Intelligent Automated Cell Extraction, Cultivation, and Storage Platform" six years ago, aiming to standardize and automate the cell preparation process in the laboratory. Since then, it has been acquiring and collecting a large amount of high-quality data. Furthermore, AI has been applied to factory management, facilitating the realization of a smarter, more efficient, and sustainable intelligent automated cell preparation subcontracting advanced process system and CDMO factory.

DrSignaliCell Inside Line, an intelligent cell preparation system, not only boasts exceptional automated cell cultivation capabilities but also features modular standalone units and customizable assembly lines as its core characteristics. This design enables not only highly automated cell cultivation but also enhances the flexibility and customization of the production process, catering to diverse production needs.

- Automated Incubation Station

- Automated Optical Inspection (AOI)

- Auto-Dispensing and Passaging Station

- Cryostorage and Thaw Station

The capacity of the cell culture chamber has been significantly increased.

Automated access prevents contamination from manual operations.

RFID access ensures accurate tracking of customer information.

AI Automated Cell Computing System.

Automated optical image recognition.

Automated media exchange enhances production capacity.

Cell automation devices prevent contamination from manual operations.

Automated freezing tube separation/storage.

Automatic low temperature control.

AI-managed inventory storage for freezing tube conditions.

Feature of product

iCell logistics container ensures remote control over time, temperature, and cell viability during the distribution process, guaranteeing the stability of cell shipment quality.

- Mobile cold chain logistics Case

- Smart cell therapy logistics system

- Cold chain logistics situation monitoring system

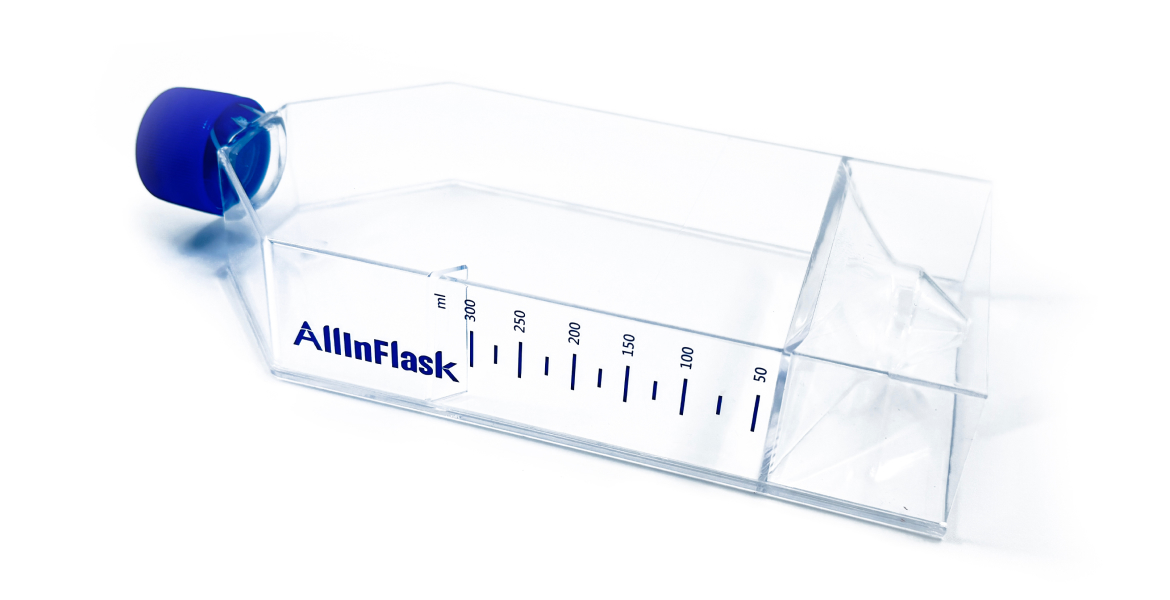

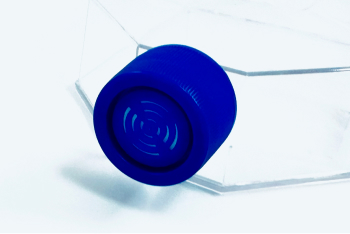

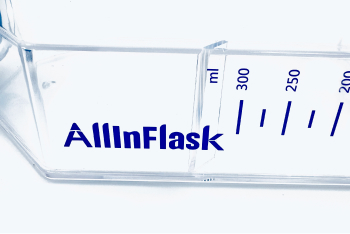

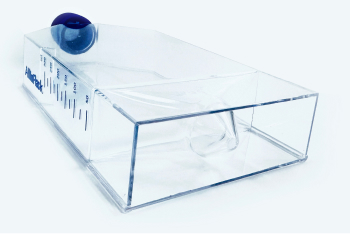

Features of AllInFlask

Features of AllInFlask

In the Process of Cell culture, AllInFlask can highly enhance efficiency, which featuring with a brand-new design with exclusive patents.